In the realm of fire safety and building materials research,

customized fire testing equipment stands as a crucial tool. It is

designed to meticulously evaluate the performance of various

materials, products, and structures when exposed to the extreme

conditions of fire. This equipment plays a vital role in industries

such as construction, automotive, aerospace, and furniture,

enabling manufacturers and researchers to make informed decisions

about fire safety and compliance.

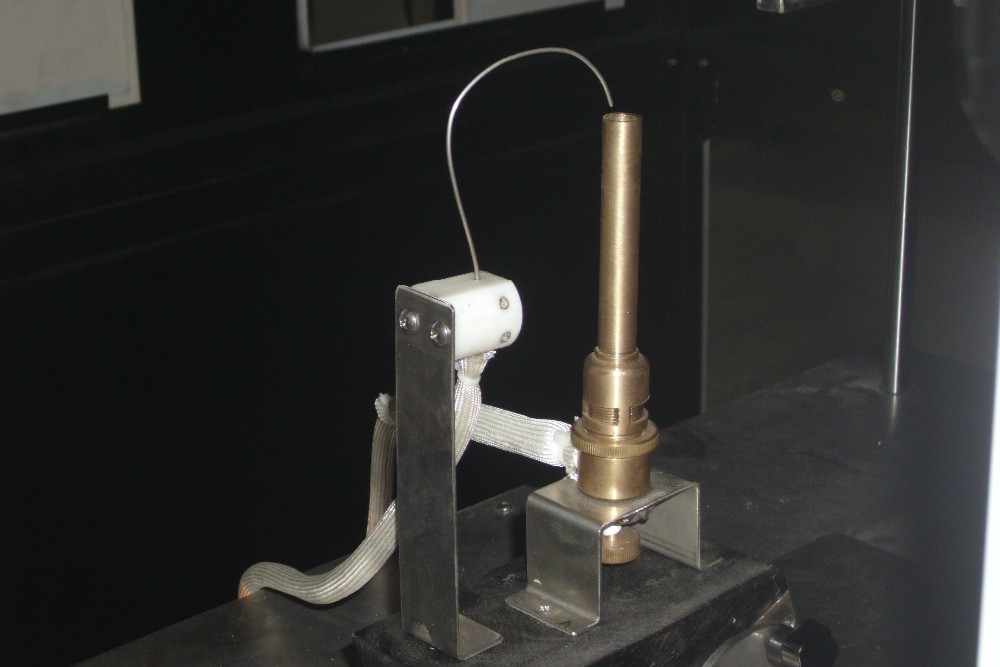

The Customized Fire Testing Equipment is a comprehensive solution

for simulating and analyzing the behavior of materials and

assemblies during a fire. It serves a wide range of clients,

including building material manufacturers, engineering firms, and

regulatory bodies. The primary purpose is to determine key

fire-related characteristics such as flame spread rate, heat

release rate, smoke production, and fire resistance time. By

subjecting samples to controlled fire scenarios, it helps in

optimizing product designs, selecting appropriate fire-retardant

materials, and ensuring compliance with stringent fire safety

standards.

- Robust and Heat-Resistant Construction

- The equipment is built with a heavy-duty steel frame that can

withstand the intense heat and mechanical stresses generated during

fire testing. The interior lining is made of high-temperature

refractory materials, capable of withstanding temperatures up to

1500°C. The door is a double-layered, insulated structure with a

reliable sealing mechanism to prevent heat leakage and ensure the

integrity of the test environment. A viewing window, made of

heat-strengthened glass, allows for real-time observation of the

test without compromising safety. The overall design is optimized

for easy access and maintenance, with removable panels and

accessible components.

- Precision Temperature and Heat Flux Control

- Temperature Control: The equipment can accurately control the

temperature within the test chamber, ranging from ambient

temperature to 1200°C, with an accuracy of ±5°C. It utilizes

advanced heating elements and a sophisticated temperature control

system, which includes multiple thermocouples strategically placed

to monitor and adjust the temperature. The control panel allows for

the programming of custom temperature profiles, such as ramping up

the temperature at a specific rate or maintaining a constant

temperature for a defined period.

- Heat Flux Control: To simulate different fire intensities, the

equipment can adjust the heat flux. It can generate heat fluxes

ranging from 10 kW/m² to 100 kW/m², enabling the testing of

materials under various levels of thermal stress. The heat flux is

precisely calibrated and controlled, ensuring reproducible and

accurate test results.

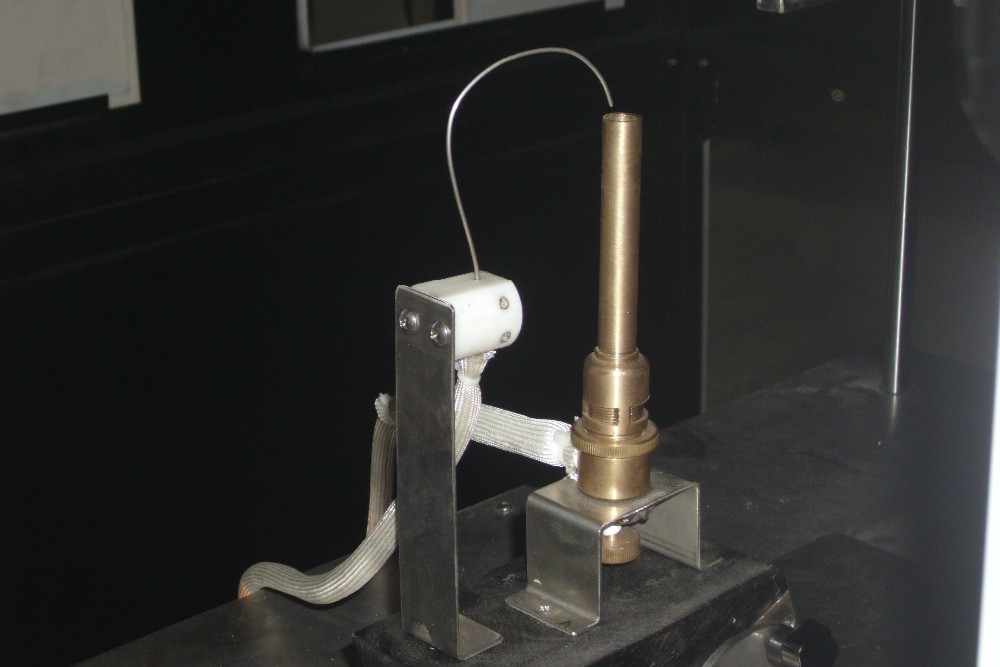

- Advanced Instrumentation and Data Acquisition

- The equipment is equipped with a suite of sensors to measure

different parameters during the fire test. It includes sensors for

temperature, heat flux, smoke density, oxygen concentration, and

gas emissions. These sensors are connected to a high-speed data

acquisition system that records and stores the data in real-time.

The data acquisition system has a sampling rate of up to 1000

samples per second, ensuring that even the most rapid changes in

parameters are captured. The collected data can be analyzed using

specialized software, which provides detailed reports and graphical

representations of the test results.

- Fire Propagation and Suppression Testing Capabilities

- The equipment can simulate the spread of fire across a surface or

through a material. It allows for the testing of different ignition

sources and fire propagation scenarios, such as horizontal and

vertical flame spread. Additionally, it can be used to evaluate the

effectiveness of fire suppression systems, such as sprinklers and

fire extinguishers. The equipment can be configured to introduce

water or other extinguishing agents at specific times during the

test to observe their impact on the fire.

- Compliance with Industry Standards

- The Customized Fire Testing Equipment is designed to comply with a

wide range of international and national fire safety standards,

such as ASTM E84, ISO 5658, and UL 94. This ensures that the test

results are recognized and accepted by regulatory bodies and

industry stakeholders. The equipment can be customized to meet

specific standard requirements, allowing for seamless integration

into existing testing protocols.

- Chamber Size and Capacity: The equipment is available in different chamber sizes to

accommodate various sample sizes and geometries. The smallest

chambers have a volume of a few cubic meters, suitable for testing

small components or specimens, while larger chambers can have

volumes exceeding 10 cubic meters, enabling the testing of

full-scale building assemblies or large industrial products. The

interior dimensions are carefully designed to ensure proper air

circulation and uniform heat distribution.

- Temperature Range and Ramp Rate: As mentioned earlier, the temperature can be controlled from

ambient to 1200°C. The ramp rate can be adjusted from 1°C per

minute to 50°C per minute, depending on the test requirements. For

example, a slow ramp rate may be used to simulate a smoldering

fire, while a rapid ramp rate can mimic a flashover condition.

- Heat Flux Range and Accuracy: The heat flux can be adjusted from 10 kW/m² to 100 kW/m², with an

accuracy of ±5% of the set value. This wide range allows for

testing materials under both mild and severe fire conditions.

- Data Acquisition Rate and Resolution: The data acquisition system samples at a rate of 1000 samples per

second, with a resolution of 0.1°C for temperature, 0.1 kW/m² for

heat flux, and 0.1% for smoke density and gas concentrations. This

high-resolution data capture provides detailed insights into the

fire behavior of the tested samples.

- Fire Testing Standards Compliance: The equipment complies with ASTM E84 for surface burning

characteristics, ISO 5658 for flame spread, and UL 94 for plastics

flammability. It can also be adapted to meet other relevant

standards, such as EN 13501 for fire classification of building

products.

- Accurate Simulation of Fire Scenarios

- The equipment provides a highly accurate and reproducible

simulation of real-world fire conditions. By precisely controlling

temperature, heat flux, and other parameters, it allows for the

evaluation of how materials and products will respond to fire. For

example, it can determine if a building material will contribute to

the spread of fire or if a product will release toxic gases during

combustion. This information is essential for architects,

engineers, and manufacturers to make informed decisions about fire

safety in their designs and products.

- Enhanced Product Development and Quality Assurance

- Through comprehensive fire testing, manufacturers can identify and

address potential fire safety issues in their products. If a

material shows a high flame spread rate or excessive smoke

production, they can modify the formulation or design to improve

its fire resistance. This leads to the development of safer and

more compliant products, reducing the risk of fire-related

accidents and ensuring customer satisfaction. The equipment also

serves as a valuable tool for quality control, ensuring that each

batch of products meets the required fire safety standards.

- Support for Regulatory Compliance and Certification

- Regulatory bodies rely on accurate fire test results to enforce

fire safety regulations. The Customized Fire Testing Equipment

enables manufacturers to conduct tests in accordance with

recognized standards, providing the necessary data for regulatory

compliance and product certification. This helps in building a

safer built environment and promoting public safety.

- Stringent Manufacturing Process

- The fire testing equipment is manufactured under strict quality

control procedures. Each component, from the heating elements to

the sensors and control panel, is carefully sourced and inspected

for quality and performance. The assembly process is carried out by

trained technicians in a clean and controlled environment. The

equipment undergoes a series of calibration and validation tests

during the manufacturing process to ensure that it meets the

required accuracy and performance standards.

- The calibration of the temperature, heat flux, and other sensors is

a critical part of the manufacturing process. It is performed using

traceable reference standards that are calibrated to the highest

levels of accuracy, guaranteeing the reproducibility of the test

results. Rigorous quality audits and inspections are conducted at

various stages of production to maintain the highest level of

product quality and compliance with fire safety standards.

- Quality Certification and Validation

Our equipment has obtained relevant quality certifications and has

been validated by independent fire testing laboratories. It has

been proven to provide accurate and reliable test results,

conforming to the relevant industry standards. We also continuously

update and improve our product based on the latest technological

advancements and customer feedback from the fire safety industry to

ensure its long-term performance and compliance.

- Building Materials Testing

- A construction material manufacturer used the Customized Fire

Testing Equipment to test a new type of insulation material. The

tests revealed that the material had a lower heat release rate and

smoke production compared to traditional insulation materials. This

led to the successful marketing of the new product as a more

fire-safe alternative, meeting the increasing demand for

sustainable and fire-resistant building materials.

- A flooring company tested their laminate flooring samples. The

testing identified that the flooring had a high flame spread rate.

By adding a fire-retardant coating and modifying the core material,

they were able to improve the fire performance of the flooring,

ensuring compliance with building codes and enhancing the safety of

their customers.

- Automotive and Aerospace Industries

- An automotive parts manufacturer tested their interior trim

materials. The tests showed that certain materials released toxic

gases during combustion. By switching to a different material and

conducting further fire tests, they were able to improve the fire

safety of the vehicle interiors, reducing the risk of injury or

death in the event of a fire.

- An aerospace company tested the fire resistance of their aircraft

cabin materials. The equipment allowed them to simulate the extreme

conditions of a cabin fire and evaluate the performance of

different materials and fire suppression systems. This led to the

development of more fire-resistant cabin designs, enhancing the

safety of passengers and crew.

- Furniture and Textile Testing

- A furniture manufacturer tested their upholstery fabrics. The

testing determined that some fabrics had a poor fire resistance

rating. By using fire-retardant-treated fabrics and testing them

again, they were able were able to improve the fire safety of their

furniture products, providing peace of mind to consumers.

- A textile company tested their industrial curtains. The Customized

Fire Testing Equipment helped them optimize the curtain's

fire-retardant properties, ensuring that they could be used in

high-risk industrial environments where fire safety is of utmost

importance.

- Pre-Sales Technical Consultation

Our team of fire safety experts provides in-depth technical

consultations to help customers understand the capabilities and

suitability of the Customized Fire Testing Equipment for their

specific testing needs. We offer demonstrations and training,

tailored to the fire safety industry, to familiarize customers with

the operation and functionality of the equipment before purchase.

We also assist in selecting the appropriate test methods and

accessories based on the materials or products to be tested. - After-Sales Service and Maintenance

We offer comprehensive after-sales service, including on-site

installation and commissioning. Our technicians are available for

regular maintenance, calibration, and emergency repairs. We provide

spare parts and upgrades to keep the test equipment operating at

peak performance. We also offer service contracts that include

preventive maintenance and priority technical support, ensuring the

long-term reliability and availability of the equipment for fire

testing. - Training and Technical Support

We conduct training programs for new users to ensure they can

effectively operate the Customized Fire Testing Equipment and

interpret the test results. Our technical support team is available

24/7 to answer questions, provide troubleshooting assistance, and

offer guidance on test method optimization and compliance with fire

safety standards. We also provide software updates and support for

the data acquisition and analysis systems, enabling customers to

take full advantage of the latest features and technologies in fire

testing.

The Customized Fire Testing Equipment is an essential asset for any

organization involved in fire safety testing and product

development. If you are looking to enhance your fire testing

capabilities, ensure compliance with industry standards, or drive

innovation in fire safety, this is the ideal solution. Contact us

today to learn more and get a customized quotation. Let us help you

unlock the full potential of your fire safety testing and product

quality assurance.